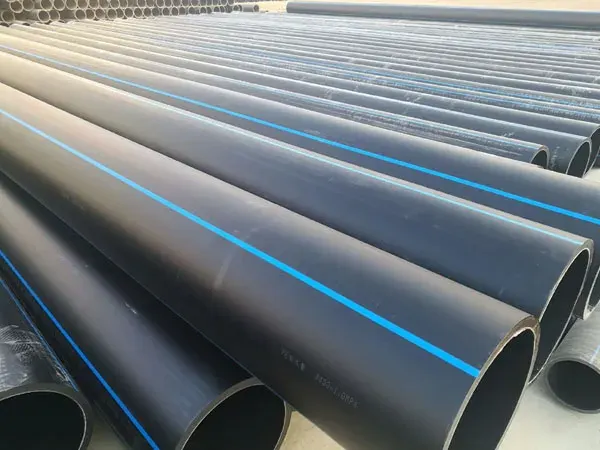

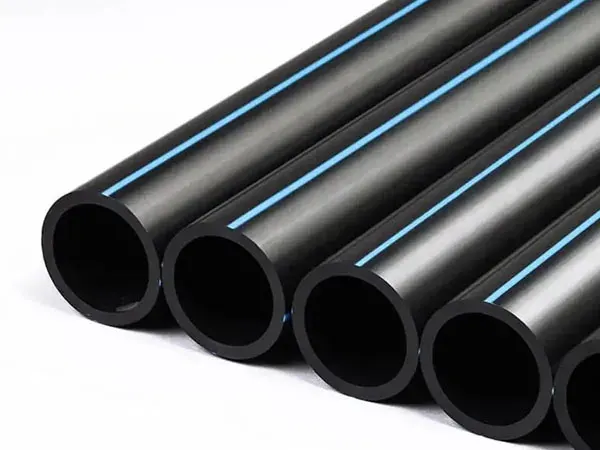

PE water supply pipe

1. Welding: During hot-melt connection, the temperature must reach 210±10℃, and care should be taken to avoid excessive scorching.

2. Buried: When working in pipe trenches, necessary safety measures must be taken into consideration.

3.It is recommended to use water as the pressure test medium. During the test, measures should be taken to prevent pipeline movement or damage.

4. Positioning: Polyethylene materials cannot be controlled by magnetic positioning equipment. Other methods can be used to detect polyethylene pipelines, including tracer lines, marking tapes, detection tapes, line markings, electronic marking systems and voice-activated pipelines.

PE PIPES Ø20-800

PE PIPES Ø20-800

PE PIPES Ø20-800

PE PIPES Ø20-800

PE PIPES Ø20-800

PE PIPES Ø20-800

PE PIPES Ø20-800

PE PIPES Ø20-800

Things to note when using PE water supply pipes

1. Welding: During hot-melt connection, the temperature must reach 210±10℃, and care should be taken to avoid excessive scorching.

2. Buried: When working in pipe trenches, necessary safety measures must be taken into consideration.

3. Test: It is recommended to use water as the pressure test medium. During the test, measures should be taken to prevent pipeline movement or damage.

4. Positioning: Polyethylene materials cannot be controlled by magnetic positioning equipment. Other methods can be used to detect polyethylene pipelines, including tracer lines, marking tapes, detection tapes, line markings, electronic marking systems and voice-activated pipeline tracing methods. .

5. Air pressure: HDPE pipes cannot be used in high-pressure gas transportation fields.

6. Application scope: HDPE pipes are not recommended in some situations. Please consult the supplier for its chemical corrosion resistance.

7. Static electricity: HDPE pipes are mixed with high static electricity. In flammable and explosive gas situations, corresponding measures should be taken to eliminate static electricity.

8. Impact performance: HDPE pipes have good impact resistance. If you use a hammer to hit the pipe, you should be aware that the pipe will produce a certain amount of resilience.

9. Coiled: The coiled small-diameter HDPE pipe stores energy like a spring. If the packaging tape is cut, it will produce a large rebound force.

10. Storage: If pipes must be stacked and stored, excessive stacking should be avoided and should be stacked in straight rows. If the pipes are not stacked properly, the pipes may be deformed.

11. Weight: Although HDPE pipes are lighter than other traditional pipes, they still have a certain weight, so care should be taken during handling and construction.

12. Unloading: Correct unloading facilities must be used, and all tools used for handling should be checked to see if they meet the requirements.